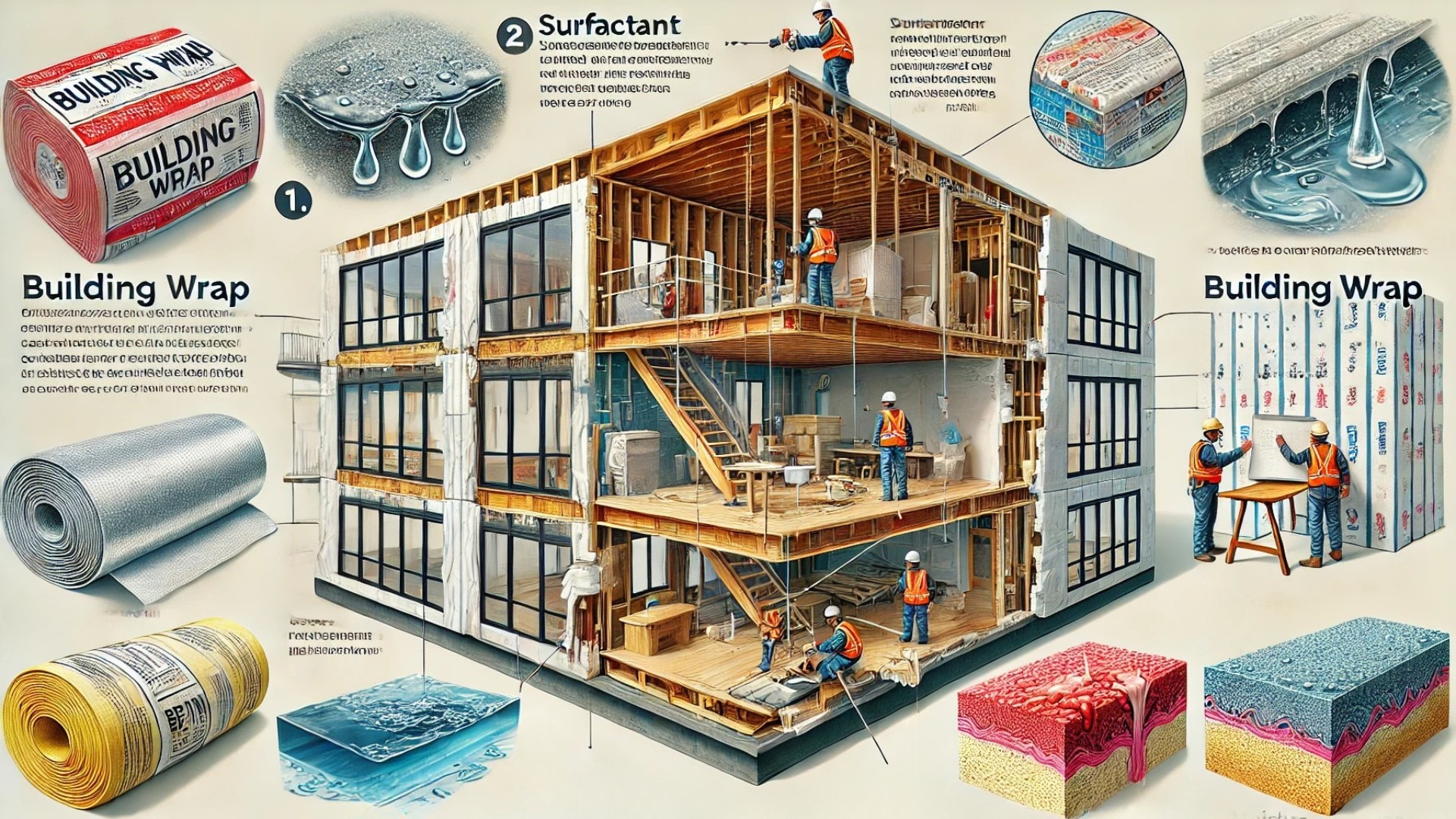

Understanding Surfactants: A Key to Building Wrap Performance

Building wraps are essential components in construction, serving as the first line of defense against moisture intrusion and air infiltration. However, few are aware of the often-overlooked impact of surfactants on these materials. Surfactants, or surface-active agents, reduce the surface tension of liquids, thereby enabling moisture to penetrate building wraps more easily. Common surfactants include wood extractives and chemicals found in detergents or soaps used for cleaning, posing a significant threat to a building's long-term integrity.

Why Surfactant Resistance Matters in Building Wraps

The importance of surfactant resistance in building wraps cannot be overstated. Surfactants can cause “wetting,” which leads to decreased water repellency in the wrap material. Once moisture penetrates the building envelope, the potential for structural damage, mold growth, and overall deterioration increases significantly, threatening the health and safety of occupants. According to industry expert Joseph Lstiburek, managing the entry of surfactants is vital in maintaining the performance of building wraps.

Choosing the Right Building Wrap for Maximum Durability

When selecting a building wrap, it's imperative to pay attention to its surfactant resistance capabilities. Not all wraps are created equal. For example, TYPAR BuildingWrap and Barricade® Wrap Plus are engineered with specialized coatings that provide superior resistance to surfactants. This resistance is validated in third-party tests that demonstrate significant disparities in performance against washing solutions. By investing in wraps designed to withstand surfactants, builders can significantly enhance the durability and performance of the building.

Best Practices for Protecting Building Wrap Against Surfactants

Even with the right product selection, several installation practices can help minimize surfactant-induced issues. Lstiburek recommends techniques such as back-priming wood materials to isolate surfactants and ensuring there is an airspace between wooden elements and the wrap. Additionally, stucco should not be installed directly on building wraps to avoid altering surface properties that impact moisture compliance. Adhering to best practices ensures the building wrap performs optimally, keeping the structure dry and healthy.

The Future of Building Wraps: Trends and Innovations

As the construction industry continues to evolve, innovations around the performance of building wraps will become paramount. Beyond surfactant resistance, factors such as tear resistance, UV stability, and moisture management are pivotal for enhancing building longevity. The ongoing refinement of materials and installation best practices is crucial to meet modern energy standards and ensure sustainable building practices. Adopting superior building wraps can yield significant return on investment for property owners, by reducing maintenance costs and extending the lifespan of buildings.

Final Thoughts: Making Informed Building Choices

In conclusion, understanding the impact of surfactants on building wrap performance is vital for contractors and builders alike. By selecting the right materials and adhering to proper installation methods, industry professionals can combat moisture intrusion effectively and uphold the structural integrity of buildings. As the stakes in construction continue to rise, staying informed on surfactant resistance will be pivotal in establishing durable, high-performance structures for future generations.

Add Row

Add Row  Add

Add

Add Row

Add Row  Add Element

Add Element

Write A Comment